COMPANY

Virginia Transformer and Georgia Transformer Corp is “the engineering firm that makes transformers”. With a history in custom-design and construction of power transformers since 1971, we have firmly established ourselves as one of the leading U.S. transformer manufacturers. Our four state-of-the-art North American facilities produce power transformers for any conceivable application – GSU, substations, auto-transformers, grounding transformers, drive duty, rectifier, exciter, voltage regulator, just to name a few – and our product line runs all the way from 300 KVA up to 400 MVA /345 kV class for core type liquid filled, 1,400 MVA / 500kV shell type liquid filled and up to 20 MVA/35 kV for dry-type.

Our Vision

Our Vision is to be an internationally recognized manufacturer and supplier of high quality specialized power transformers, associated equipment and services by fulfilling our commitments to the customer and our employees through continued growth and improvement.

Our Value

We pride ourselves on premium quality, customer service and our expert engineering staff that works from 15,000 designs we have archived to assist us in designing the perfect transformer to meet your specific needs. We supply transformers for utility, industrial, transit, commercial, alternative energy. Engineers making transformers for Engineers.

Our Mission

To build the most reliable power transformer, designed and manufactured by engineers and technicians; using time tested processes and train and develop our employees to provide a premium product ensuring defect free performance on time to every customer.

Expanding Goal

As we look forward to the future, our focus on perfection, customer service, ownership cost, and best delivery of power transformers remains the same. The demand of our expanding client base provides continuous incentives to the VTC / GTC teams to maintain the quality and customer service and drive satisfaction.

Company History

Virginia Transformer has over five decades of experience in the custom design and manufacturing of power transformers. And that experience extends across every market – utility, industrial, commercial, alternative energy, marine/offshore, transit, data centers. Anywhere that electrical power needs to be generated, transmitted, or distributed, you’ll find our transformers in operation. We offer solutions for the widest range of markets and applications of any power transformer company in North America. Whatever your particular needs are, we can supply the perfect power transformer to meet them.

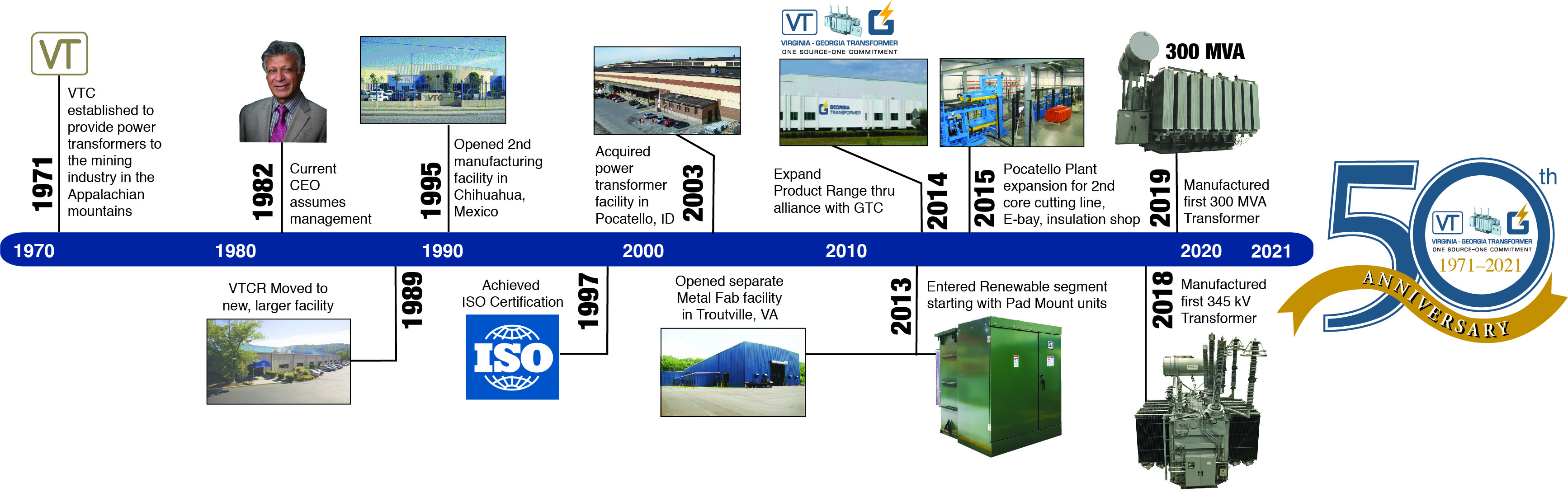

1971

VTC ESTABLISHED AND INCORPORATED

During the 70’s, our customer base and product scope became more diversified, adding rectifier duty transformers and reactors for adjustable frequency drives and NEMA RI9 extra heavy duty traction for metro rails. Most major urban transit systems today employ transformers built by VTC.

1997

Achieved ISO Certification and company expansion

The 90’s witnessed entry into the demanding Utility market, as customers sought to find additional suppliers for their requirements of high quality and a cost efficient manufacturer. During this decade VTC moved to a new facility and its current corporate headquarters – a 120,000 square foot custom designed facility for modern transformer manufacturing. VTC further expanded in 1995 by adding a second custom manufacturing facility in Chihuahua, Mexico. This modern state-of-the-art 60,000 square foot operation, designed from the ground up as a transformer plant, has been ISO certified from the beginning. Visiting customers have proclaimed it to be one of the finest facilities for manufacturing transformers in North America.

GTC GRAND RE-OPENING

2015

EXPAND PRODUCT RANGE THRU ALLIANCE WITH GTC

With the addition of GTC the VTC family became the largest Power Transformer Corporation by annual capacity in North America.

With over 100 experienced degreed engineers using over 15,000 designs, four integrated transformer facilities with state of the art equipment in North America and a manufacturing area of 667,000 Sq. Ft and 47,000 MVA annual capacity we provide power transformers up to 1,400MVA 500kV to Utilities and Industrial markets in North America.

Utilizing newer technology, state of the art equipment, highly qualified & experienced engineers, overall improved processes allows us to provide the most reliable products and the shortest lead time in the Industry.

We have a well-balanced approach focusing in Utilities, Industrial and Commercial, Renewables, O&G.

1989

CEO, Mr. JAIN TAKES THE HELM AND EXPANDING PRODUCT LINE

Beginning in the 80’s, our current CEO, Mr. Jain, took the helm at VTC. Our product range was further expanded to include industrial and commercial power transformers for small power applications, including those with automatic load tap changing requirements, and our trademarked fully encapsulated coil UNICLAD® (dry type) transformer.

2003

another facility added

Virginia Transformer, Pocatello, Idaho – VTC acquired this plant from UST West in 2003. This WAS a repair facility. VTC has invested $20 million in the plant over the years. Today it is the best equipped 230KV, 200MVA plant in North America, at 1050KV BIL the plant can produce 345KV.

2013

Opened separate facility for Tank Fab

A new facility was developed 11 miles from the Roanoke, VA plant on 25 acres. The tank fabrication, sand blasting and paint process was relocated to a new building in Troutville, VA in December of 2013. The tank fab plant is equipped with a welding robot that delivers leak free welds, down draft sand blast booth for personnel safety and a SP-10 finish per SSPC standards for premium paint adhesion.

GTC RIBBON CUTTING CEREMONY

Management

Our strategy is to create a culture of customer commitment and continuous improvement by maintaining a safe, efficient, and satisfying workplace for our employees. To do this, we must be good corporate citizens by respecting the environment and the laws of the location where we are located and where our products are being used.

.jpg)